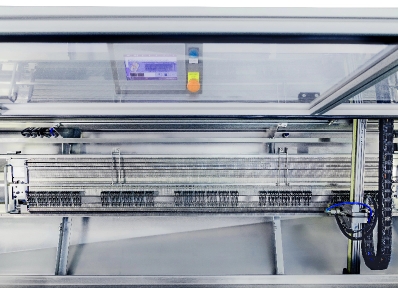

The closed circuit of washing fluid allows it to be reused for several hours, reducing energy and consumption waste: the same water is heated only once inside the deposit and the high pressure guarantees temperature retention.

Furthermore, H2G's patented technology significantly reduces machine downtime. No longer having to remove the needles, the average time is one hour for cleaning two compact needlebeds, up to a maximum of 7 hours for a Wholegarment with 5 needle beds, complete with Loopresser-bed. But not only that: a clean needlebed means producing more efficiently, faster and without breaking needles, which, remaining in the original position, ensure uniform creation of the garment.

Finally, staff will no longer have to come into contact with dangerous chemical agents such as Kerosene, used for years to clean every single needle, and will be able to spend their time on more profitable activities for the company.